Analysis - Oxygen

Analysis

Analysis

Analysis

Oxygen sensors and transmitters

Products for high accuracy oxygen measurement in all industries

The measurement of dissolved oxygen is essential for quality assurance and process control in numerous applications such as aeration control, fermentation or inertization. We provide instruments for reliable and accurate oxygen analysis over all measurement ranges from oxygen traces to high oxygen concentrations and for all conditions such as hazardous areas or hygienic processes. Check out our broad offering of dissolved oxygen sensors and transmitters.

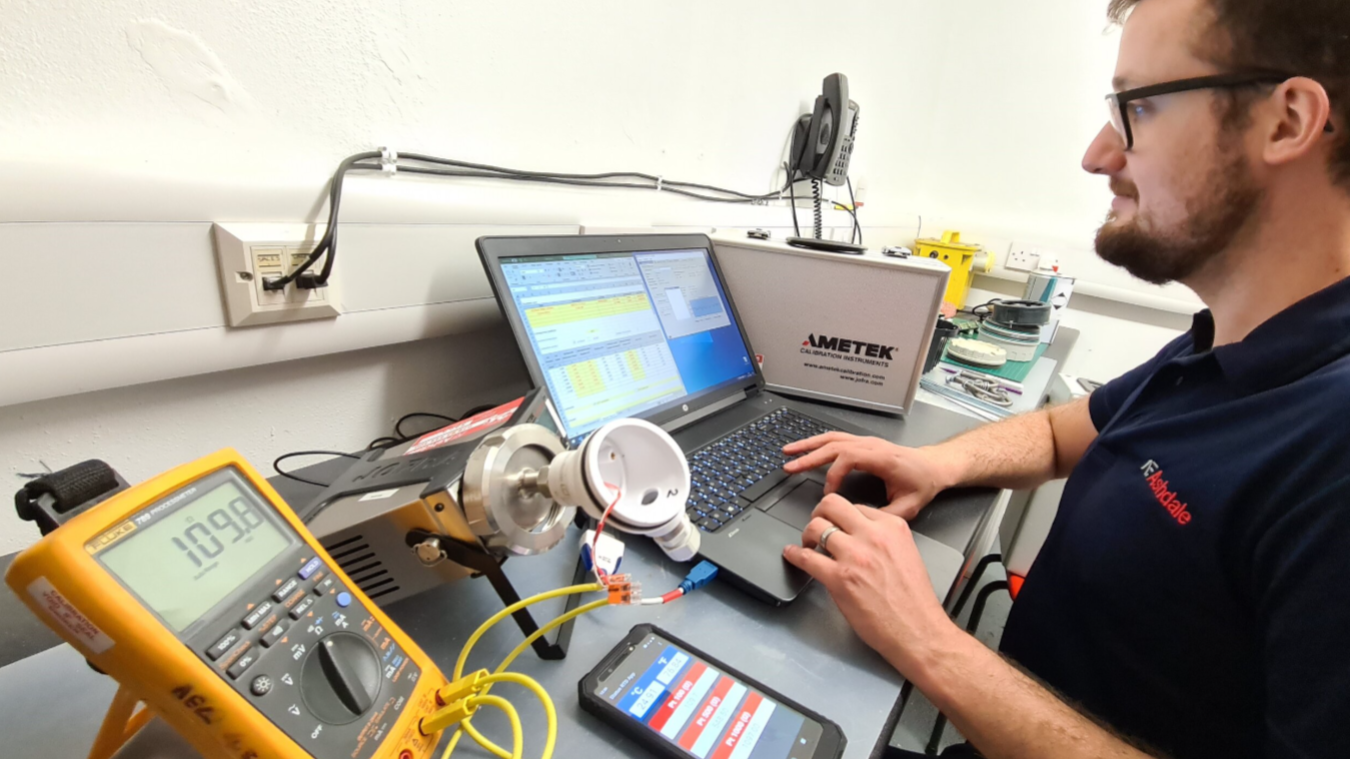

Ashdale have been using the extensive range of Endress+Hauser dissolved oxygen monitoring equipment to help industry measure and control oxygen saturation of liquids. Ashdale have had a lot of case studies in the Pharmeceutical industry with units performing well in the top ten pharmacem plants in Northern Ireland.

How to select oxygen sensors

Oxygen sensors and transmitters are used in many industries such as water, wastewater, chemicals, power, life sciences, pharma, food & beverage and fish farming. The sensor selection depends on your preferences: amperometric oxygen sensors measure accurately and linearly from oxygen traces up to high oxygen concentrations. However, they do require regular maintenance. The advantages of optical oxygen sensors are the fast availability of stable measured values and extremely low maintenance.

Oxygen measurement with amperometric sensors

Amperometric oxygen probes comprise a working electrode and a counter electrode. They are surrounded by an electrolytic liquid in a common chamber and a direct voltage is applied to both. Oxygen permeates from the medium into the electrolyte through a membrane and is converted to a current at the working electrode. The counter electrode keeps the system running by means of a chemical equivalence reaction. The resulting current is proportional to the oxygen partial pressure in the medium.

Oxygen measurement with optical sensors

Optical oxygen probes use the fluorescence quenching method and feature an LED, a photodiode and a separating section to the medium that is covered by an oxygen-permeable layer. The layer contains marker molecules that are excited by an orange light and respond with a dark red fluorescence light. Oxygen molecules attach to the marker molecules and attenuate (quench) the fluorescence light. The photodiode then detects the light intensity which reflects the oxygen partial pressure in the medium.

Compensation of electrode aging or LED aging

Over the time each oxygen sensor can suffer from aging effects leading to measurement drifts:

The counter electrode of amperometric probes can be covered with a silver bromide layer that reduces the effective voltage.

The measurement LED of optical probes can lose its intensity.

To compensate these effects, we offer amperometric sensors with an additional reference electrode and optical sensors with a reference LED. This way, our sensors deliver accurate and reliable values over a long period.

Benefits

We offer oxygen sensors and transmitters that meet all requirements from basic functionality up to multichannel and multiparameter measurement.

Our oxygen transmitters process the measuring signal of each oxygen sensor and display it as you prefer: as oxygen partial pressure, oxygen concentration or oxygen percentage saturation.

To provide you with full flexibility, our dissolved oxygen probes are designed both for use in channels and basins as well as for installation in pipes and tanks.

Choose between a wide range of oxygen assemblies for all fields of applications: fixed installation assemblies, immersion assemblies, flow assemblies and retractable assemblies.

Easy to use oxygen calibration standards help you to reliably adjust, calibrate and verify your sensors and to determine the zero point of each oxygen sensor.

Ashdale are proud to represent Endress+Hauser in Northern Ireland.

Our technical team are OEM trained and certified so you can trust us to provide the very best support for sales & service.

If you have an application, please get touch we love solving problems !

4-channel transmitter Liquiline CM444 Predecessor: CCM360 , Sludge level CUM750

1-/2-channel transmitter Liquiline CM442 Predecessor: Turbimax CUE21 , Sludge level CUC101 , Liquisys M CUM253 , Liquisys M CUM223 , ISEmax CAM40 , Liquisys M COM223F , Liquisys M COM253F , Stamosens CSM750 , Turbidity Transmitter CUM740 , Stamosens CNM750

Manual or automatic retractable assembly Cleanfit CPA871 Predecessor: Cleanfit P CPA472 , Cleanfit P CPA471

Manual or automatic retractable assembly Cleanfit CPA875 Predecessor: Cleanfit H CPA475 , Probfit CPA465

Predecessor: 51515945 , Memobase CYZ41D , 51515945

Digital oxygen sensor Oxymax COS22D Predecessor: Oxymax COS21D , Oxymax W COS71

Digital oxygen sensor Oxymax COS51D Predecessor: Oxymax W COS31

Immersion assembly Flexdip CYA112 Predecessor: CPA530 , CPA610 , Dipfit W CYA611

Modular holder system Flexdip CYH112 Predecessor: Universal CYH101

1-channel transmitter Liquiline M CM42 Predecessor: Mycom S CLM153 , Mycom S CPM153 , CLD431 , Mypro CLM431 , Mypro CPM431

Multichannel transmitter Liquiline CM44P Predecessor: Memograph CVM40

Dissolved oxygen assembly Cleanfit COA451 Predecessor: Probfit COA461

Dissolved oxygen transmitter Liquisys COM223 Predecessor: COM121 , COM120 , COM220 , COM221

Dissolved oxygen transmitter Liquisys COM253 Predecessor: COM141S , COM240S , COM340 , COM141 , COM130 , COM140 , COM240 , COM151 , COM252

Dissolved oxygen sensor Oxymax COS41 Predecessor: COS4 , COS4HD

Dissolved oxygen sensor Oxymax COS61 Predecessor: Oxymax W COS31

Process assembly Unifit CPA442 Predecessor: CPA440 , CPA441 Successor: Unifit CPA842

Manual retractable assembly Cleanfit CPA450 Predecessor: CPA461

Process assembly Ecofit CPA640 Predecessor: CPA642

Process assembly Unifit CPA842 Predecessor: Unifit H CPA442

Cleaning unit Cleanfit Control CYC25 Predecessor: Topclean S CPC30

Digital service tool Memocheck CYP02D Successor: CYP02E

Digital service and qualification tool Memocheck Sim CYP03D Predecessor: Memocheck Plus CYP01D