PILZ Safety relay PNOZ

PNOZ – The optimum safety solution for each requirement

The safety relays PNOZ monitor safety functions such as E-STOP, safety gates, light barriers, light grids, two-hand controls, pressure sensitive mats, speed, standstill and much more too. Every day, PNOZ safety relays prove themselves in millions of applications worldwide.

In 1987 Pilz patented the first emergency stop relay to protect man and machine. That was a milestone in safety technology. PNOZ safety relays quickly progressed to be the world’s most commonly used safety relays. The PNOZ brand is now synonymous with safety relays. PNOZ – The original!

Continual development led from these simple devices to the configurable small control systems PNOZmulti, the worldwide safety standard for machinery.

Ashdale are proud to represent PILZ in Northern Ireland.

Our technical team are OEM trained and certified so you can trust us to provide the very best support for sales & service.

If you have an application, please get touch we love solving problems !

E-STOP relay for maximum functionality in minimum width

The safety relays PNOZsigma combine many years of experience with today's very latest safety technology. You can achieve maximum safety and cost-effectiveness with minimum effort, thanks to the emergency stop relay.

With particularly narrow housing widths and diverse functionality packed into each unit, the emergency stop relay provides maximum functionality in minimum width. You can thereby implement safety technology faster, with greater flexibility and more efficiently, while saving space.

Monitoring of E-STOP, safety gates, light barriers

Two-hand monitoring

Safe speed monitor PNOZ s30 Time monitoring

The safety relay PNOZ s5Safe voltage monitor

PNOZ s60Safety relay PNOZ s50 –

Safe brake control Contact expansion modules

Accessories available

Customised safety for your application.

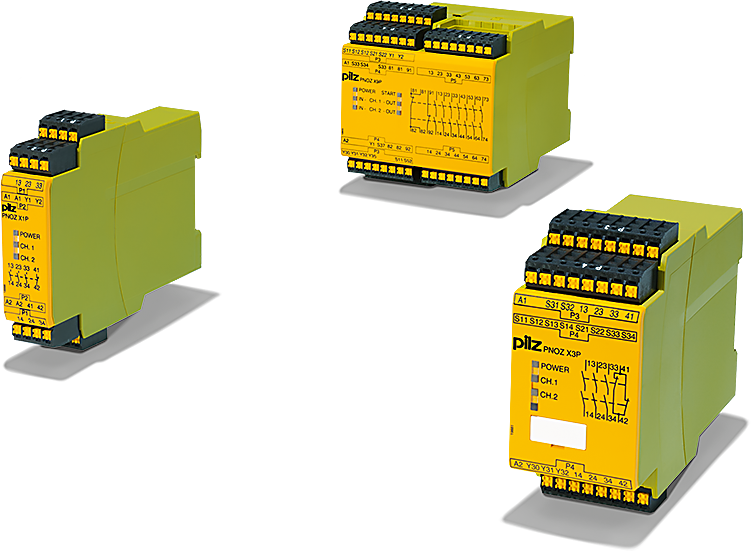

PNOZ X safety relays are proven through their reliability and sturdiness. They are used in a wide range of applications and in the most diverse safety applications. Use one PNOZ X per safety function. The technical features are based on voltage-free, electromechanical contacts with 2 relay technology. The sizes vary from 22.5 to 90 mm, the number of contacts from two to eight. Whatever your safety requirement – PNOZ X has already proved itself a million times over in the rugged everyday industrial environment.

To monitor E-STOP, safety gates, light barriers

Safety relays PNOZ

Two-hand monitoring

Pressure-sensitive mat monitoring

Standstill and voltage monitoring

Time monitoring

Muting controller

Contact expansion modules

Accessories available

PNOZcompact safety relay

A space-saving, high-performance safety relay

Its compact design saves you space in the control cabinet

Simple installation and maintenance saves you time

Tool-free installation because the unit is simply snapped onto the top hat rail

Maximum safety thanks to Performance Level (PL) e of EN ISO 13849-1, Safety Integrity Level (SIL) CL claim limit 3 of IEC 62061

Connection without separate documentation, made possible by the block diagram with connection example on the housing

Quicker service via QR code on the unit for direct access

PNOZelog safety relay

Solid-state safety

The PNOZelog product range combines the experience of electromechanical safety relays with the advantages of modern electronics. With PNOZelog you can reliably monitor up to four safety functions. Wear-resistance, safety and long service life ensure that it is cost-effective to use. Save on wiring! PNOZelog can be easily linked through logic operations. Increase the availability of your machine thanks to expanded diagnostics. Power-up tests, self-checking and runtime tests also guarantee maximum safety.

Take advantage of the shock and vibration-resistant safety relay PNOZelog. Particularly in mobile applications where vibration levels are high. The use of modern electronics ensures the units are durable and maintenance-free.

PNOZpower safety relays

Switching high loads safely

Use the modular safety relay PNOZpower to monitor E-STOP, safety gates and light barriers. With PNOZpower you can switch currents of up to 16 A AC/DC per contact. An overall breaking capacity of 40 A is available per module.

In each case, external contactors and contactor combinations are no longer required. The base unit processes the inputs; the output modules are specifically matched to the respective load. The number and capacity of the required safety contacts can be scaled, depending on the application. You can connect a maximum of five modules to the base unit. Modules are wired to the base unit via an internal bus system.

PNOZpower can do so much more! Save costs on applications with more than 5 safety contacts. It's easy to add extra contacts to the system. Thanks to the modular structure, this can be done without the need for additional wiring.

Maximum safety for long cable routes – With PLIDdys!

Line inspection devices

The safe line inspection device PLIDdys provides safe power-up on twowire connections, providing maximum safety on long cable routes. With PLIDdys, unintended power-up or plant start-up can be excluded in the event of an error. This is particularly beneficial on interlinked plants or on plant sections distributed over a wide area, which may not always be clearly visible.

Line inspection device: The benefits at a glance

All potential wiring errors are detected through constant line inspection by PLIDdys, no need for customised tests

PLIDdys can be looped into the existing wiring, so few additional costs

Easy to integrate into existing plants thanks to its small dimensions

Saves costs, as the prevailing periphery can be retained

Suitable for cable lengths up to 3,000 metres